Demos

Demo videos

These demos provide an inside look at how WagonFit automates modern railway gauging. From real-time clearance measurements to complete swept-volume visualizations, the videos show how the platform brings accuracy, speed, and clarity to one of the most critical stages of vehicle-infrastructure evaluation.

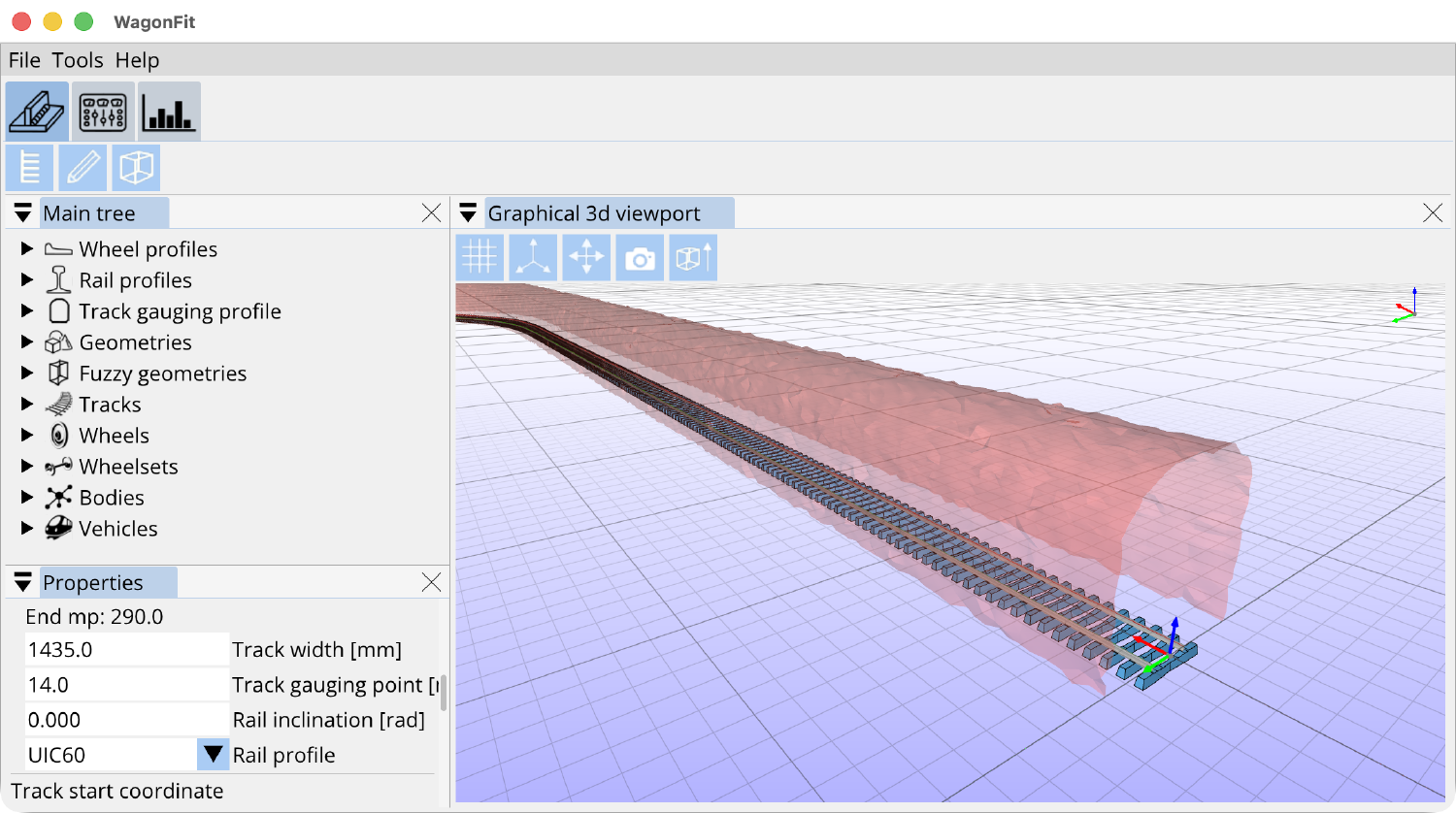

Swept-Volume Generation from User-Defined Vehicle Motion

One of WagonFit’s key capabilities is the generation of a complete 3D swept volume as the vehicle advances along the track. Instead of relying on static profiles, the software uses user-defined kinematic inputs—such as roll, pitch, and yaw—to compute the exact space the vehicle would occupy along its trajectory. The resulting swept envelope provides a detailed volumetric representation of vehicle motion, helping engineers detect potential clashes with infrastructure, validate designs with greater accuracy, and export the full volume to CAD for further integration.

Direct LiDAR Integration for Clearance Assessment

Here, WagonFit incorporates LiDAR-measured infrastructure directly into the gauging workflow. A tramway vehicle travels through a tunnel represented as a high-resolution point cloud, and the software computes distances between the vehicle envelope and the surrounding geometry. The point cloud is then colorized by clearance, offering immediate visual insight into available space and potential clashes. With native support for LiDAR data—without external preprocessing—WagonFit enables engineers to work directly with real-world geometry and perform accurate clearance evaluations within a single environment.

Clearance Evaluation on Curved Station Platforms

This section demonstrates how WagonFit handles the complex geometry of curved platforms. A vehicle with shared bogies moves through the station while the software continuously measures the distance between the vehicle envelope and the platform edge. These measurements help engineers ensure that the vehicle does not contact the platform and that the passenger gap remains within safe limits. Curved platforms are typically difficult to assess due to varying offsets and angles, but WagonFit provides a fast, visual, and reliable way to analyze these clearances directly within the 3D environment.

Generation of Limiting 3D Clearance Surfaces

This example shows how WagonFit derives a limiting 3D surface from a vehicle running inside a track with a defined gauging profile. The video displays two synchronized views: the upper section shows the vehicle progressing through the tunnel, while the lower section illustrates the carbody geometry adapting to the constraints imposed by the profile. At the end of the process, WagonFit computes a limiting 3D surface representing the maximum allowable vehicle occupation without infringing the track envelope. This surface can be exported to CAD environments as a precise reference for design validation. The calculation can also incorporate multiple track inputs—such as curves, cant, tunnel geometry, and clearance rules—to produce a comprehensive, scenario-specific 3D envelope for engineering use.

Vehicle-platform gap optimization

This example illustrates how WagonFit models the interaction between a vehicle’s lateral profile and a curved station platform. As the vehicle progresses along the track, the software continuously computes the exact clearance at each point and generates a moulded side profile derived from these interactions. At the end of the process, WagonFit produces the resulting deformation-based outline, capturing the areas where the platform–vehicle gap becomes most critical. This final profile can be exported directly to CAD environments, supporting detailed design optimisation and platform–vehicle integration studies. The calculation offers an intuitive way to detect critical zones, refine geometries, and make informed engineering decisions with a workflow that is significantly simpler than traditional methods.